About Global Lift Used Forklifts Connecticut

Global Lift Connecticut - Purchasing a forklift is not to be taken lightly. A forklift is a big capital expense, and a complex machinery with a motor strong enough to carry out heavy-lifting tasks. The price tag for a forklift varies from $10,000 to $30,000, comparable to the cost of a small truck. If purchasing a second-hand forklift, be sure to have it checked for potential mechanical problems.

There are two different types of forklift motor: internal combustion or electric. Forklifts with electric motors are normally more costly compared to those with internal combustion motors. The size of the motor should suit the type of work for which the forklift will be used. A forklift with a motor that is big costs much more compared to a forklift with a motor which is smaller.

Motors that utilize propane or gasoline can lift heavier weights as they are usually stronger than electric motor. The disadvantage is that gas motors tend to develop issues more frequently compared to electric motors. Depending on the price of gas or propane, gas powered forklifts could be more expensive to run compared to electric powered forklifts.

Some reliable manufacturers of forklifts are Mitsubishi Caterpillar, Crown Equipment Corp., NACCO Industries and Toyota Industries. Before making a decision, research the different manufacturers and the availability of parts. Prices, reviews and testimonials could be found on line.

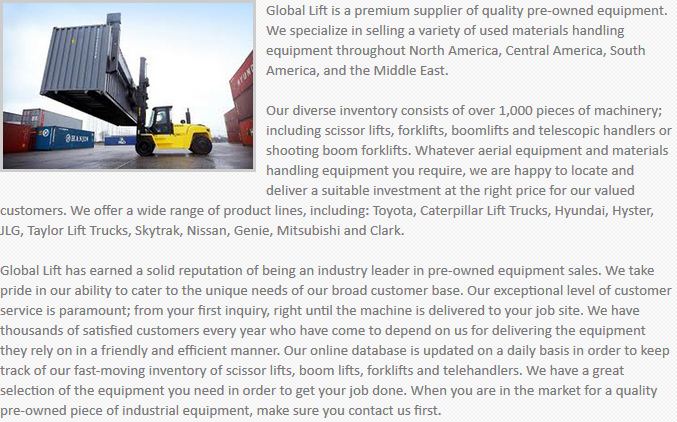

A forklift are a kind of equipment which allows an operator to easily and efficiently carry and transport objects which are bulky and heavy. Forklifts are also referred to as industrial-powered trucks. They are an important device utilized for transporting cargo and merchandise through the logistical supply chain. Forklifts are either electrically powered, or gas- or diesel-powered. Gas-powered kinds run on diesel, liquid propane gas or gasoline. Training in forklift operation and safety, such as correct fueling methods, is vital for all operators of forklifts.

There are a wide range of forklifts, each designed for different applications and settings. Kinds of forklifts consist of side loaders, narrow aisle, sit-down units and reach trucks. Your choice of a forklift depends on the particular tasks which will be carried out.

Each and every year, roughly 100 people are killed in accidents that are related to forklifts in the United States. Many more people receive serious injuries in forklift mishaps. Proper safety training is required to lessen the risk of accident.

Either gasoline, diesel, propane or battery are utilized to power forklifts. Every different type is suited to a different workplace environment.

In order to carry heavy supplies, metal forks, which come with forklifts are utilized. Possible attachments include buckets, clamps and hoists.

In warehouse environments, forklifts need to maneuver in really narrow aisles and have a tight turning radius. There are particular forklift types made for this kind of setting. Narrow aisle forklifts allow a warehouse or distribution center to provide a lot more space to merchandise.

Forklift certification really helps to ensure that businesses are following regulations and legislation. Forklift operators should go through certification prior to being permitted to operate equipment. In areas where certification is not needed by law, training is helpful for individuals seeking industrial jobs. Certified individuals are normally chosen over other applicants because of this training. Certified forklift operators are normally paid higher than individuals who are not licensed. For companies, having forklift operators who are properly trained means fewer workplace incidents, better productivity and less product damage during unloading and loading. If companies follow governmental guidelines by providing training to their staff, they can achieve higher ratings on their safety inspections, potentially decreasing insurance costs.

It is suggested that individuals get licensing through a formal forklift training program. Warehouse jobs could be easier to acquire with a license because certification shows to an employer that the individual applying has the skills necessary. A forklift license is suggested due to the benefits to both the company and the employee. A skilled operator saves resources due to fewer incidents, that means savings on expenses connected with time lost or hospitalization. A licensed forklift operator could be depended upon to work more efficiently and effectively compared to one who is not trained.

The length of a formal forklift training program would vary and depends upon a lot of things, like for example the type of forklift utilized in the instruction, class size, and experience and aptitude level of trainees. Trainees would be required to pass a written test and practical exam prior to getting the license. Upon successful completion of a formal training program, graduates would be qualified to be able to acquire a job in various industries.

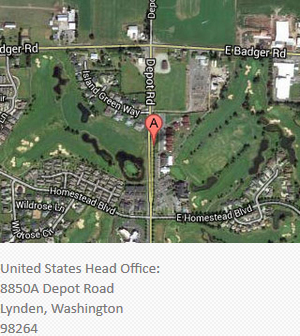

Contact Info

Fax: 1-888-029-0202

Fax: 1-888-029-0202

Questions or Comments